The introduction of the Public Charge Point Regulations in November 2023 set out legislation to ensure Charge Point Operators (CPOs) provide a consistent level of service across four main areas:

- users can easily locate the right public charge point to fit their needs.

- ease of payment across public charge points.

- consumers can be confident that public charge points will be in good working order.

- consumers can compare prices across multiple public charge point networks.

A review of the implications of the new policy areas to ensure ongoing compliance of Bender eMobility technology for the needs of the UK market has highlighted an area in which we can help CPOs achieve compliance with the regulations via our existing industrial portfolio.

Part 3: Performance requirements

Part 3 of the Public Charge Point Regulations contains the following clause:

“Reliability

7.—(1) A charge point operator must, one year from the date on which these Regulations come into force, ensure that its network of rapid charge points complies with the reliability requirement set out in paragraph (2).

(2) The reliability requirement is that the network of rapid charge points is, on average, reliable

for 99% of the time during each calendar year.”

Charge point operators must ensure they meet the reliability requirementwhich requires their rapid public charge points to be available 99% of the time. This is measured as an average across a charge point operator’s rapid network of public charge points 50kW and above. Reliability is measured using the below formula:

Where:

Differences between RCDs and RCMs

RCDs (residual current devices) are used to provide (additional) protection in electrical installations. RCDs are designed for tripping when leakage or fault currents to earth reach a certain level and therefore always cause a shutdown.

RCMs (residual current monitors) monitor residual currents in electrical installations, indicate the present value and signal when the response values are exceeded. In contrast with RCDS, RCMs are designed for signaling when a threshold is reached, not for tripping.

What is Residual Current?

Residual current is the R.M.S. value of the vector sum of the fault and leakage currents flowing through RCM/RCD.

Residual Current Monitoring principle

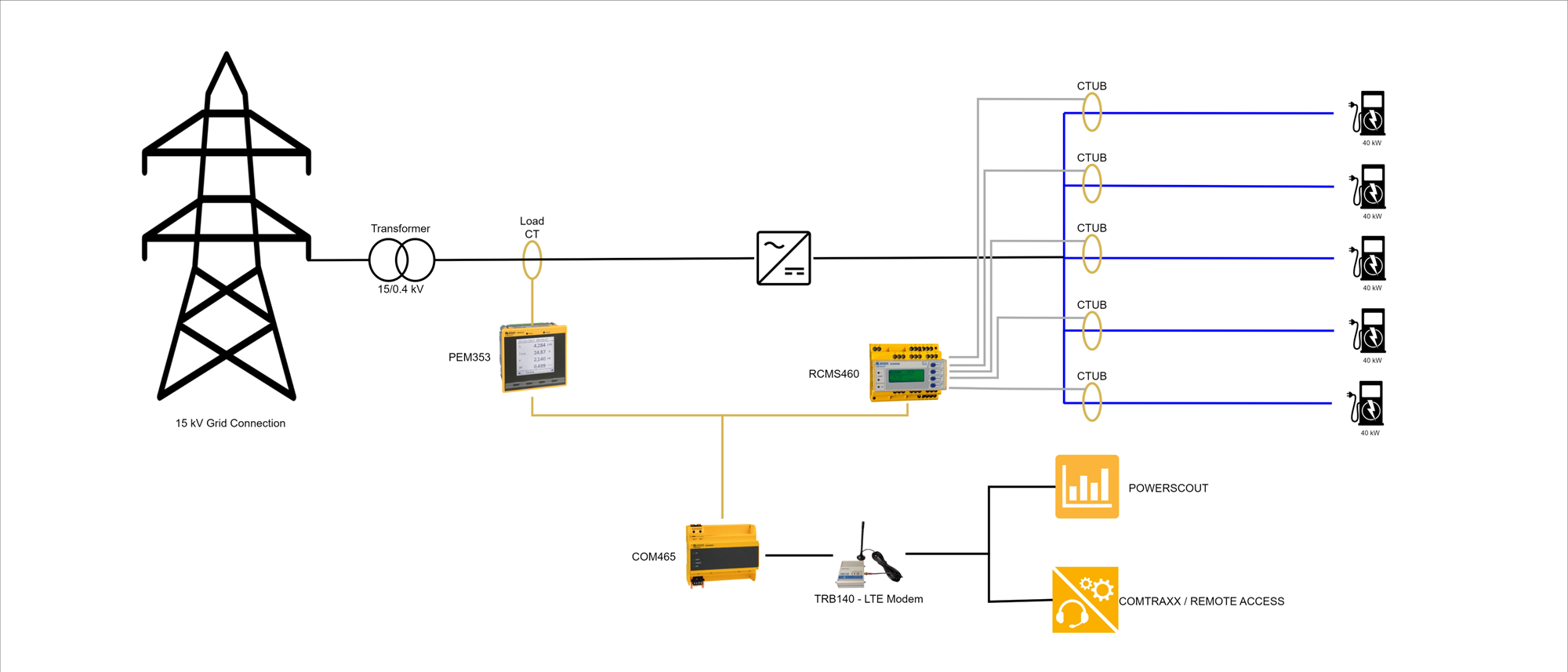

Residual current monitors are used to monitor earthed systems (TN and TT systems) for residual currents. The sum of all conductors except the protective earth conductor is measured by means of measuring current transformers. In a fault-free system, the sum of all currents is equal to zero so that no voltage is induced in the measuring current transformer. If a fault current (IΔ) flows via PE or other paths, the difference in current in the measuring current transformer generates a current flow which is detected by the RCM.

Our RCM technology is used across multiple applications where critical loads require monitoring to make systems safer, reliable and more available by providing advanced warning of developing insulation faults.

Monitoring of individual loads provides real-time, precise insulation level information, allowing for fast and accurate pinpointing of potential issues before they develop to a critical level which may result in loss of power.

Continuous system residual current monitoring is also an acceptable alternative to isolation for periodic inspection and testing – full compliance with regulations without associated disruption.

As covered earlier on, public CPOs must meet the 99% uptime metric set out by the regulations. The guidance to the Public Charge Point Regulations specifies which electric vehicle supply equipment (EVSE) statuses are included in reliability calculations, and which are exempt.

The following table shows which statuses would be considered downtime scenarios used as part of the overall reliability value measured by the regulator.

EVSE object status | Description | Interpretation |

Inoperative | The EVSE/Connector is temporarily not available for use, but not broken or defective. | The charge point is temporarily not available for use, due to an error that is inhibiting the operation of the charge point, including the ability to pay for a charge via contactless. This would typically be due to a software related issue. |

Out of order | The EVSE/Connector is currently out of order, some parts/components may be broken/defective. | The charge point is currently out of order. This would typically be due to a hardware related issue, such as a broken or defective component, that is inhibiting the operation of the charge point. This includes the ability to pay for a charge via contactless. |

As well as the downtime scenarios, there are also several statuses which are considered exempt from the data used for uptime measurement. Whilst most of these aren’t relevant for RCM, the status shown below would be relevant due to the bold text in the interpretation column.

EVSE object status | Description | Interpretation |

Unknown | No status information available (also used when offline). | CPOs may use this status in the event that an exceptional circumstance outside of the CPO’s control has been identified. This could include a power grid or communication network failure, vandalism or severe flooding. All such events must be appropriately evidenced in the charge point operator’s annual reliability report. |

By using RCM for real-time monitoring of system residual current levels, operators can demonstrate that they are proactively measuring and reacting to faults developing in their network, and can use the RCM data gathered as part of their annual reliability report to the OPSS. Advanced warning of developing insulation faults also gives CPOs a much greater time advantage to investigate and rectify faults before they reach the disconnection level of the circuit protective device and subsequent equipment downtime, which would negatively affect their reliability metrics.

All Bender RCM devices are designed and manufactured in accordance with IEC 602020: “Electrical accessories - Residual current monitors for household and similar uses (RCMs)” – see also BS7671, clause 538.4

Insulation resistance testing during periodic inspection and testing requires disconnection, is intrusive and only provides a snapshot of the system health at the time of the test. Power critical installations like data centres, processing plants and hospitals etc. either do not comply or repeatedly test the same circuits. All other tests can be carried out either with power on or with minimum disruption at circuit level.

BS7671, chapter 65: Periodic Inspection and Testing contains clause 651.2: “Where a circuit is permanently monitored by an RCM or an IMD it is not necessary to measure the insulation resistance if the functioning of the RCM or IMD is correct”

Our RCM technology can be used to fulfil the above requirements.

Regulations are now in effect which measure CPOs for compliance in a number of areas, including reliability of their charge stations. Whilst only covering equipment of 50kW and above for now, this remains under review and may well extend to all ratings in coming years.

RCD protection is already required on supplies to charge stations, however this is designed to disconnect once the fault level is reached resulting in loss of power to the charge station. A residual current monitoring system can be used to provide real-time residual current information to CPOs, allowing them to see developing faults before they reach a level which results in a power failure at their equipment.

All of this data can be used to provide remote, real-time reporting of the health of supplies to charge stations allowing CPOs to prevent unplanned downtime in line with the reliability targets set out in the new regulations.

Products

Four-channel DC, AC and pulse current sensitive residual current monitors for earthed AC, AC/DC and DC systems

Four-channel DC, AC and pulse current sensitive residual current monitors for earthed AC, AC/DC and DC systems

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| Product Overview - Residual Current Monitoring | Product Overviews | 4.2 MB | EN | 2026/02/1111.02.2026 | |

| RCMS425-D | Manuals | 5.1 MB | EN | 2025/05/2828.05.2025 | D00488 |

| RCMS425-D | Quickstarts | 1.1 MB | EN | 2025/05/0808.05.2025 | D00488 |

| RCMS425-D | Datasheets | 2.7 MB | EN | 2025/06/0202.06.2025 | D00488 |

Integrate RCM into your EVSE to detect faults early, reduce unplanned outages, and support your reporting.

Contact form