Rail signalling power: The differences between Tier 1, 2 and 3 monitoring

RS4 rail signalling power monitoring: The differences between Tier 1, 2 and 3 monitoring

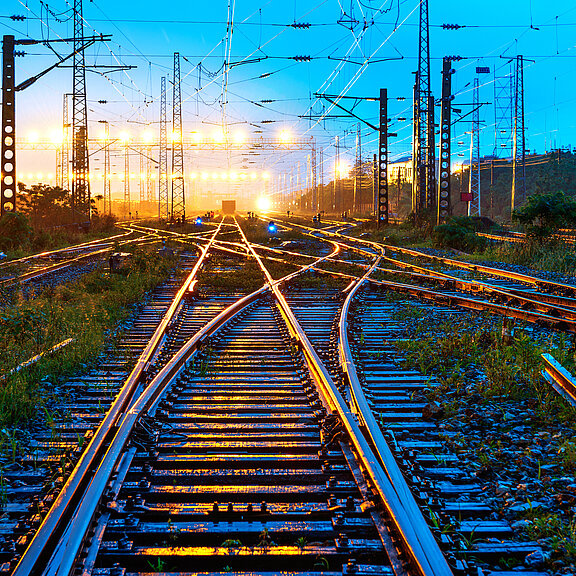

Railways require robust power systems to support signalling, points, and communications infrastructure. With extensive trackside equipment that must be protected from failure, Network Rail relies on advanced monitoring systems to assess infrastructure health and condition.

The UK rail network faces harsh conditions, including cable theft, accidental damage, and natural degradation, making fault detection a challenge. Traditionally, maintenance teams manually inspected tracks to locate failing cables. However, fault location technology transforms this process by enabling proactive maintenance, reducing downtime, and improving service reliability.

Reducing trackside maintenance with advanced fault location

The initiative to reduce trackside interventions is driven by the ability to detect emerging electrical faults earlier and pinpoint their locations more accurately. Maintenance teams can assess faults before they escalate using predictive and preventative strategies to minimise service disruptions and associated penalties.

Multi-tier fault location with RS4 technology

Network Rail regulation NR/L3/SIGELP/50001 stipulates that the insulation resistance faults identified at warning stage of <=100kΩ require intervention in 6 weeks reducing it to 24 hours for <=20kΩ level. There are further restrictions defined at higher insulation resistance levels in the maintenance management standards like NR/SPS M003.

The RS4 multi-tier solutions technology provides increased fault location capabilities to even higher levels than defined in the standards, increasing intervention time to within or over prescribed times. This means a developing fault can be addressed over a longer timescale through planned and predictive maintenance rather than waiting for a critical alarm.

The RS4 rail signalling power monitoring system is designed to meet these requirements through a multi-tier fault location approach:

Tier 3: System-wide monitoring

- Purpose: Provides an overall system insulation resistance measurement, covering multiple feeder systems and signal power supplies.

- Technology: Uses patented Bender AMP technology and Type-A current transformers (CTs) for increased sensitivity, improving fault location from 20 kΩ to 100 kΩ (vs RS3 systems).

- Application: Ideal for broad network-level monitoring, offering insight into general system health without detailed individual feeder analysis.

- Compliance: Certified under NR/L2/SIGELP/27725 and approved by Network Rail (PA05/04750).

Tier 2: Individual feeder-level monitoring

- Purpose: Enhances monitoring by measuring insulation resistance (IR) at the level of individual feeders, providing more precise fault location than Tier 3.

- Technology: Incorporates Bender Type B CTs, EDS440WNR evaluators, and COM465IP condition monitors.

- Application: Enables operators to pinpoint specific feeders experiencing degradation, reducing system-wide impact.

- Upgradability: Can be upgraded to Tier 1 by adding EDS440WNR fault evaluators and additional Type B CTs at Functional Supply Points (FSPs).

- Compliance: Certified under NR/L2/SIGELP/27725 and approved by Network Rail (PA05/04750).

Tier 1: Subsection and FSP-level precision monitoring

- Purpose: Provides the highest level of fault detection by monitoring individual cable subsections and FSPs.

- Technology: Utilises an advanced earth-fault evaluator (EDS440WNR) and Type B CTs within FSP enclosures to precisely locate insulation degradation.

- Application: Enables real-time IR measurement of cable subsections, eliminating the need for direct earth connection and ensuring comprehensive fault assessment.

- Integration: Fully compatible with Class II and Class I equipment, available in 650V mains and 110V supply options.

- Compliance: Certified under NR/L2/SIGELP/27725 and approved by Network Rail (PA05/04750).

The future of rail fault detection

RS4’s multi-tier architecture aligns with Network Rail’s commitment to reducing infrastructure failures and trackside maintenance. By continuously monitoring live rail signal power systems, the RS4 system enables:

- Proactive maintenance instead of emergency repairs.

- Reduced train delays through precise fault location.

- Safer working conditions by minimising trackside maintenance.

- Seamless integration with Network Rail’s Intelligent Infrastructure

Existing RS2/RS3 installations can be upgraded to RS4, ensuring compatibility with modern railway infrastructure and maximising the value of legacy investments.

For more details on how RS4 technology can enhance railway safety and reliability, contact our team of experts.